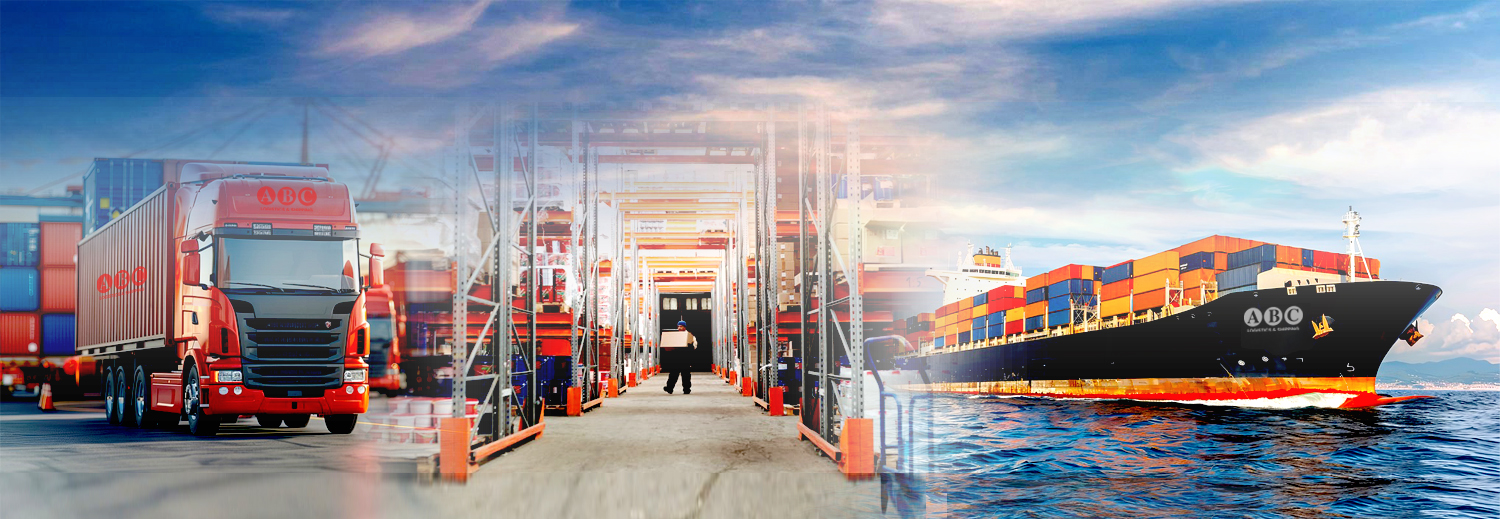

Warehousing refers to the process of storing goods and materials in a designated location, typically a warehouse until they are needed for distribution, sale, or use. It plays a crucial role in the supply chain by providing a centralized point for inventory management and distribution.

In warehousing, goods are received from suppliers, sorted, stored, and then dispatched to customers or other destinations as required. Modern warehousing facilities often utilize advanced technology such as barcode systems, RFID (Radio Frequency Identification), and automated storage and retrieval systems to improve efficiency and accuracy in inventory management.

Warehouses provide a secure and organized environment for storing goods. This includes proper shelving, pallet racks, and storage systems to maximize space utilization.

Warehouses track the movement of goods in and out of inventory, monitor stock levels, and facilitate inventory control measures to prevent stockouts or overstock situations.

Warehouses fulfil customer orders by picking, packing, and shipping goods promptly. This involves coordinating with transportation providers to ensure timely delivery.

Some warehouses engage in cross-docking, a process where incoming goods are directly transferred to outbound trucks or delivery vehicles without being stored in the warehouse. This reduces handling and storage time, improving efficiency.

Warehouses may offer additional services such as kitting, assembly, labelling, and quality inspection to add value to the products stored.

Warehouses serve as distribution centers, strategically located to efficiently reach customers and markets. They may also facilitate the consolidation of shipments from multiple suppliers before onward distribution.

Overall, warehousing is essential for optimizing the flow of goods through the supply chain, reducing costs, and enhancing customer satisfaction through efficient inventory management and timely order fulfillment.